核心工具 | AIAG | VDA |

| APQP | AIAG APQP | VDA 2-PPA + VDA MLA |

| FMEA | AIAG FMEA AIAG-VDA FMEA | VDA 4 (FMEA + FTA) AIAG-VDA FMEA |

| SPC | AIAG SPC | VDA 4 |

| MSA | AIAG MSA | VDA 5 |

| PPAP | AIAG PPAP | VDA 2-PPA + VDA MLA |

| QFD | -- | VDA 4 + VDA 11 |

| SOP | -- | VDA 2-PPA |

| MLA | -- | VDA-MLA (VDA-RGA) |

| DOE | -- | VDA 4 + VDA 11 |

| PPA | -- | VDA 2-PPA |

| SW | -- | VDA 13-A-SPICE |

| RPP | -- | VDA-RPP |

| Poka-Yoke | VDA-RPP | |

| 1 | Introduction (簡介) |

| 2 | Instructions for use (使用說明) |

| 2.1 | Definition of process audit (過程稽核的定義) |

| 2.2 | Area of application for a process audit (過程稽核的應用領域) |

| 2.3 | Classification process audit – Potential analysis (過程稽核分類 - 潛能分析) |

| 2.4 | Identification of process risks (risk analysis) (過程風險的識別 (風險分析)) |

| 3 | Requirements for process auditors (過程稽核的要求) |

| 3.1 | Auditor qualification (稽核員資格) |

| 3.1.1 | Internal process auditors (內部過程稽核員) |

| 3.1.2 | Supplier auditor (供應者稽核) |

| 3.1.3 | Process auditing as an external service auditor (擔任過程稽核的外部服務稽核員) |

| 3.2 | Code of conduct for auditors (稽核員職業守則) |

| 4 | Audit process (稽核過程) |

| 4.1 | Audit programme (稽核方案) |

| 4.2 | Audit request (稽核申請) |

| 4.3 | Audit preparation (稽核準備) |

| 4.4 | Conducting the audit (稽核的執行) |

| 4.5 | Evaluation (評估) |

| 4.6 | Presentation of results (結果的簡報) |

| 4.7 | Follow up and closure (跟催與結案) |

| 5 | Potential Analysis (P1) (潛能分析 (P1)) |

| 5.1 | Definition of potential analysis (潛能分析的定義) |

| 5.2 | Requirements (要求) |

| 5.3 | Preparation (準備) |

| 5.4 | Operational sequence of a potential analysis (潛能分析的運作次序) |

| 5.5 | Evaluation of a potential analysis (潛能分析的評估) |

| 5.6 | Follow-up activities after contract award (合約生效後的跟催活動) |

| 6 | Evaluating a process audit for material products (務料產品過程稽核的評估) |

| 6.1 | Evaluation of the individual questions (個別問題的評估) |

| 6.2 | Detailed Evaluation and downgrading rules (詳細評估與降級規則) |

| 6.3 | Overall level of compliance and downgrading rules (整體符合性等級與降級規則) |

| 6.4 | Evaluation of Product Groups (產品群組的評估) |

| 6.5 | Using the questionnaire (Process elements P2 to P7) |

| 7 | Questionnaire (問卷) |

| 7.1 | Questionnaire (問卷) |

| 7.2 | Project management (P2) (專案管理 (P2)) |

| 7.3 | Planning the product and process development (P3) (產品與過程發展的規劃 (P3)) |

| 7.4 | Implementation of the product and process development (P4) (產品與過程發展的執行 (P4)) |

| 7.5 | Supplier management (P5) (供應者管理 (P5)) |

| 7.6 | Process analysis production (P6) (過程分析生產 (P6)) |

| 7.7 | Customer care, customer satisfaction, service (P7) (顧客關懷、顧客滿意度、服務 (P7)) |

| 8 | Process audit services (服務過程稽核) |

| 8.1 | Overview questionnaire for services (服務整體問卷) |

| 8.2 | Project management (D2) (專案管理 (D2)) |

| 8.3 | Planning of the service development (D3) (服務發展的規劃 (D3)) |

| 8.4 | Implementation of the service / service development (D4) (服務/服務發展的實施 (D4)) |

| 8.5 | Supplier Management (D5) (供應者管理 (D5)) |

| 8.6 | Providing the Service (D6) (服務提供 (D6)) |

| 8.7 | Customer care, customer satisfaction, service (D7) (顧客關懷、顧客滿意度、服務 (D7)) |

| 8.8 | Application and evaluation of process audit for services (服務業過程稽核的應用與評估) |

| 8.8.1 | Evaluation of the individual questions (個別問題的評估) |

| 8.8.2 | Detailed evaluation and downgrading rules (詳細評估與降級規則) |

| 8.8.3 | Overall level of performance (整體績效等級) |

| 9 | Assessment forms (評鑑表單) |

| 9.1 | Process audit for material products (務料產品的過程稽核) |

| 9.2 | Potential analysis (P1) as an extract from the VDA questionnaire (從 VDA 問卷萃取一部芬的潛能分析 (P1)) |

| 10 | Best practice / lesson learned (最佳實務/學習心得) |

| 10.1 | Example of a supplier self-assessment (供應者自我評鑑的範例) |

| 10.2 | Knowledge database (知識資料庫) |

| 11 | Glossary (詞彙) |

| 11.1 | Terms and definiton (名詞與定義) |

| 11.2 | List of abbreviations (縮寫字清單) |

| 12 | Downloads (下載) |

| 13 | Overview Matrix (全貌矩陣) |

輸入 | 過程步驟 | 輸出 |

| 根據稽核要求,產生稽核方案 | 稽核方案 |

| 目的 (Objective) |

| 職責 (Responsibility) |

| 稽核方案負責人員儲蓄調整稽核時程,以及相對應的計畫資源。 |

| 描述 (Description) |

| |

| 方法/文檔 (Method / documentation) |

| 稽核方案。 |

Technical progress, customer expectations and new production technologies lead to increasing demands in the entire chain of customer and supplier processes. This continually poses the quality management of companies with new and challenging tasks. It is necessary to ensure that robust processes are in place and secure throughout the manufacturing and supply chain. | 技術進步、客戶期望和新的生產技術,導致整個顧客和供應者過程鏈的需要不斷增加,對公司的品質管理不斷地提出新的和具有挑戰性的任務,因此必須在整個製造和供應鏈中,確保具有到位且安全的強健過程。 |

The process audit following VDA 6.3 is an important and well established method for the analysis of processes. The process audit exhibits a high effectiveness through the evaluation of the real performance of the processes on site, by examining the interfaces and the supporting functions in the project and serial phase. | 依照 VDA 6.3 進行過程稽核,是一個重要且完善的過程分析方法。藉由檢查專案和系列階段中的介面和支援功能,通過評估現場過程的實際績效,展現出高有效性的過程稽核。 |

After a first edition was published in 1998 a complete revision was made in 2010. With the 2016 edition our colllective experience has been used to update and optimize the volume. | 自從 VDA 6.3 第 1 版在 1998 年發行之後,2010 年做了完全的改版。2016 年版則是集合大家的經驗進行更新及最適化的文件。 |

The process standard VDA 6.8 contains the current questionnaire and evaluation criteria and additionally the requirements for the qualification of process auditors and the preparation and implementation of process audits. | 過程標準 VDA 6.3 包含了現行的調查問卷和評估標準,以及過程審核員資格的要求和過程審核的準備與實施。 |

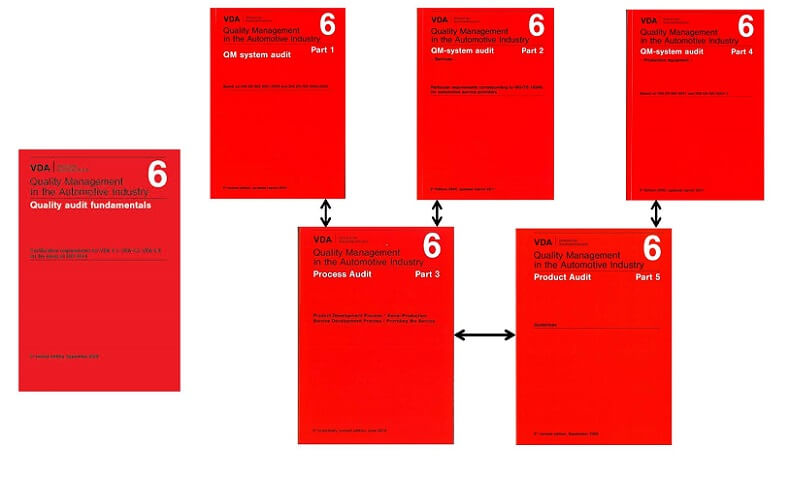

The process audit following VDA 6.3 is part of the VDA Strategy "Quality standard for the German automotive industry" (VDA 6.x Volumes). | 依照 VDA 6.3 實施過程審核,是 VDA 策略「德國車輛產業品質標準」(VDA 6.x 卷)的一部分。 |

There is agreement between automotive manufacturers and suppliers on the execution of audits in accordance with this publication. | 車輛製造者和供應者之間達成一項協議,根據本文件執行各項稽核。 |

The well established Audit Standard VDA 6.3 from 2010 has been completely revised. With the 2016 edition our collective experience has been utilised to update and optimize the volumn. | 2010 年建立的稽核標準 VDA 6.3 :2010 已經完全改版,2016 年版是蒐集大家的經驗進行更新及最適化的文件。 |

The interaction of the process audit standard VDA 6.3 with other VDA publications, especially, "Maturity Level Assurance for New Parts (MLA)" and "Robust Production Processes (RPP)", has been strengthened. In this volume the requirements are given for process specific content. Thus the distinction between process and system audits is made clear. | VDA 6.3 過程稽核標準與其他 VDA 文件的互動已經強化,特別是「新零件成熟度水準保證」(MLA)與「強健生產過程」(RPP)。本卷提供過程規定內容的要求,因此使過程稽核和系統稽核之間的區隔更為明確。 |

Furthermore the questionnaire has been revised both in content and structure. The inferface between hardware and software in products with embedded software has been included. However, for a detailed evaluation of software development other methods are to be used (Automotive SPICE, CMMI). | 另外,本卷的問卷的內容和結構都已經完全改版,包括了內含嵌入式軟體產品的硬體與軟體之間的介面。不過,軟體發展的詳細評估,則要使用其他的方法(車輛 SPICE、CMMI)。 |

The content of the process audit for services has also been revised. | 服務類過程稽核的內容同樣也完成改版。 |

The calculation of results has been adjusted. All questions are now weighted equally. The generic approach has been deleted. The classification system using A, B, and C and the reliable downgrading rules have been retained. | 稽核結果的計算方式已經調整,所有的問題都具有相同的權重,通用方式已經刪除,使用 A、B、與 C 的分類系統和可信的降級規則,則予以完全保留。 |

Due to the revision, the current edition does not allow audit results from the previous VDA 6.3 from 2010 to be directly transferred into calculations from the edition presented here. | 由於改版的關係,2010 年以後按照 VDA 6.3 先前版本的稽核結果,不得直接轉移到現有版本所敘述的計算式中。 |

Within this volume, the requirements for the qualification of process auditors are given in more detail. Different requirements for internal and external process auditors are given. The qualification of auditors regarding this audit standard is set out. Focus is also given to the actual implementation of the audit. | 在本卷中,提供了更詳細的過程稽核員資格要求,以及內部與外部過程稽核員之間的差異,設定了有關本稽核標準稽核員的鑑定資格,同時聚焦在實際執行稽核方面。 |

Assessment questions in the areas of sustainable development, compliance with social standards, environmental protection and conservation of resources are not contained in the questionnaire. For these areas there are special monitoring methods as well as legal and normative directives. However, if the auditor observes obvious points that are contrary to the requirements of this process audit standard or have a negative impact on the product characteristics, these should be documented and included in the evaluation. | 有關永續發展、社會標準符合性、環境保護、及資源保存等領域的評鑑問題,並不包括在問卷之中。針對這些領域,已經有特殊的監視方法,以及法律和規範性指令。不過,當稽核員觀察到有明顯地違反了本過程稽核標準要求的狀況,或者對產品特性有負面影響時,都應該建檔並納入評估。 |

The other volumes of the VDA series and the AIAG manuals are given as a reference in a matrix that relates to the questionnaire. | 本卷最後提供了各項問卷與 VDA 系列其他卷本和 AIAG 手冊的相關矩陣,作為參考之用。 |

Current information and the latest status of the VDA publications can be found on the VDA QMC website. | VDA 文件的現有資訊和最新狀態,可上 VDA QMC 網站查詢。 |

A process audit is a method for impartial analysis and evaluation of the performance of a product development cycle and the effectiveness for the defined product. | 過程稽核是一種可以公正地針對產品開發週期績效以及定義產品有效性進行分析和評估的方法。 |

The goal of the process audit is to check the conformity of the requirements / process step with the specifications. Any deviations that are detected are documented as audit findings and evaluated based on the product risk and / or the process risk. The evaluation must consider what the resulting risks would be if the findings indicate non-compliant products. | 過程稽核的目標在於檢查(產品)需求/過程步驟對於規範的符合性。檢測到的任何偏差都要加以記錄列為稽核發現結果,並根據產品風險及/或過程風險進行評估。如果發現結果顯示不符合產品時,評估必須考慮到可能造成的風險為何。 |

Process audits can be used internally as well externally throughout the entire product life cycle. The questionnaire is constructed in such a way that it can be used for small and medium-sized companies as well as for large corporations. | 過程稽核可以應用在整個產品產品生命週期的內部稽核以及外部稽核。稽核問卷的構建方式,使其可用於中小型公司以及大型企業。 |

Using the VDA 6.3 process audit, the processes in the product development process (PEP) can be analysed and muturity level and proces risks evaluated before SOP. | 使用 VDA 6.3 過程稽核,可以在 SOP 之前分析產品開發過程(PEP)中的各項過程,並且評估成熟度等級和過程風險。 |

After SOP the process audit can be used for example for the regular monitoring of the serial production and event oritented failure analysis and elimination. The use of the individual process elements in the project phase can vary in content and implementation period between internal and / or external applications. | 生產開始 (SOP) 之後,過程稽核可用於例如批量生產的定期監視和事件導向失效分析與消除。在專案階段所使用的各個過程要項,應用在內部稽核及/或外部稽核可以有不同的內容和實施週期。 |

Fig. 2.1 shows possible use of the individual process elements within the context of a specific project. | 圖 2.1 顯示各個過程要項在規定專案的內涵中的可能使用方式。 |

For the potential analysis (X1) see chapter 5. | 針對潛能分析 (X1) 參見第 5 章。 |

The focus of the use of process elements P2 to P4 is on the early phase of the product development process (X2 + X3). Both the process element P2 and the process element P3 are used ideally to analyse the plannig activities after contracting (X2). | 過程要項 P2 到 P4 的使用聚焦在是產品發展過程的初期階段 (X2 + X3)。過程要項 P2 和過程要項 P3 適用於簽約後規劃活動 (X2) 的分析。 |

The process element P4 can be scheduled at a later time to analyse and evaluate (X3) the implementation of the planning activities in accordance with process element P3. | 過程要項 P4 可以安排在稍後的時間進行,用以分析和評估根據過程要項 P3 規劃的活動的實現結果 (X3)。 |

The breakdown of the process elements offers the possibility to assess the planning activities as well as the implementation/realisation. The application of the process elements P2 to P4 is utilised for early identification of maturity level and process risks from the contracting stage to SOP and thus supports the process optimisation from the project phase onwards. | 過程要項的細分,提供了評估規劃活動以及實施/實現的可能性。從簽約階段到開始生產 (SOP),可以採用過程要項 P2 到 P4,早期識別成熟度等級及過程風險,從而支援專案後續階段的過程最適化。 |

The process elements P5 to P7 (X4) are ideally applied at SOP analogous/according to maturity level ML 6 from VDA-MLA. | 過程要項 P5 至 P7 (X4),類比/根據 VDA-MLA 的成熟度等級 ML6,適合應用在開始生產 (SOP) 時。 |

As part of the serial production process elements P5 to P7 (X5) can be used for the regular monitoring of the serial process or to support an event-based reactive process analysis. | 作為批量生產過程的一部分,過程要項 P5 至 P7(X5)可用於例行監視序列過程,或支援事件為基礎反應式過程分析。 |

In principle, each user/company has the right to align the use of the process elements to meet their needs during the product development and production. | 原則上,每一個使用者/公司都有權調整過程要項的使用,以滿足其產品發展和生產的需要。 |

As can be seen from figure 2.2, an analysis of potential (P1) can be carried out before a contract is awarded. The questionnaire, with a reduced scope, can be used to assess potential suppliers who may be suitable as serial production suppliers. Because these are potential suppliers the audit, when necessary must based on other processes / products which should be comparable with the product to be supplied. | 從圖 2.2 可以看出,在合約簽署之前可以進行潛能 (P1) 分析。經過縮小範圍的稽核問卷,可用於評鑑可能適合作為批量生產供應者的潛在供應者。因為必要時,有些潛在供應者必須根據與待供應產品相當的其他過程/產品進行審核工作。 |

In a process audit, the effect of the individual processes on the product is decisive and the assessment must therefore be made from the standpoint of the product risks involved. For this reason, the potential risks within the process must be determined as early as the preparations for the audit (see also Section 4.3), so that they may be assessed adequately in the process audit itself. | 在過程稽核中,個別過程對產品的影響是早就決定的,因此必須從所涉及產品風險的角度進行評鑑。 基於此一原因,在準備稽核時必須儘早決定過程中的潛在風險(同時參見第 4.3 節),以便在過程稽核時可以對其進行充分的評估。 |

An example of the turtle model using process element P6 is shown below, but the model can used for all process elements. | 過程要項 P6 使用烏龜圖模型的範例如下圖所示,不過此一模型可使用於所有的過程要項。 |

Firstly a description is given of what "input" (see questionnaire sub-element P6.1) is converted into an "output" (see questionnaire sub-element P6.6) by the process. This is expanded by considering the following questions: | 首先,提供將「輸入」(參見問卷子項 P6.1)轉換為「輸出」(參見問子項 P6.6)過程的說明,然後考慮下述問題加以展開: |

|

|

|

|

|

|

|

|

In a second stage the potential risks arising from these questions are determined. These potential risks must then be questioned and evaluated in the audit. This ensures a reasonable degree of risk minimisation. The auditor as well as the audit team should make use of their know-how to identify potential product and process risks that could affect the product quality. This allows focusing on specific points and/or limiting the scope of the audit. Interfaces have a substantial influlence. At interfaces information can be lost or incorrect information can be passed on. | 在第二階段,決定這些問題產生的潛在風險。然後,在稽核中必須質疑和評估這些潛在風險,如這確保將風險減小化到合理的程度。稽核員以及稽核團隊,應該用他們的專業知識來識別會影響產品品質的潛在產品和過程風險。如此可以聚焦在特定議題點及/或限制稽核的範圍。介面會有很大的影響,在介面處,資訊可能會滅失、或者通過不正確的資訊。 |

| 歡迎光臨 睿地可靠度論壇(TW-REDI Forum) (http://m1.kdi.tw/) | Powered by Discuz! X2 |